How Earth Observation Technology is Transforming the Mining Industry

Earth Observation (EO) technology has emerged as a transformative solution, offering mining companies access to high-resolution, real-time data that fundamentally reshapes decision-making across the entire mining lifecycle. From initial exploration through to post-closure monitoring, satellite-based insights are enabling a new paradigm of operational excellence that balances productivity with sustainability.

Revolutionising Mineral Exploration Through Advanced Imaging

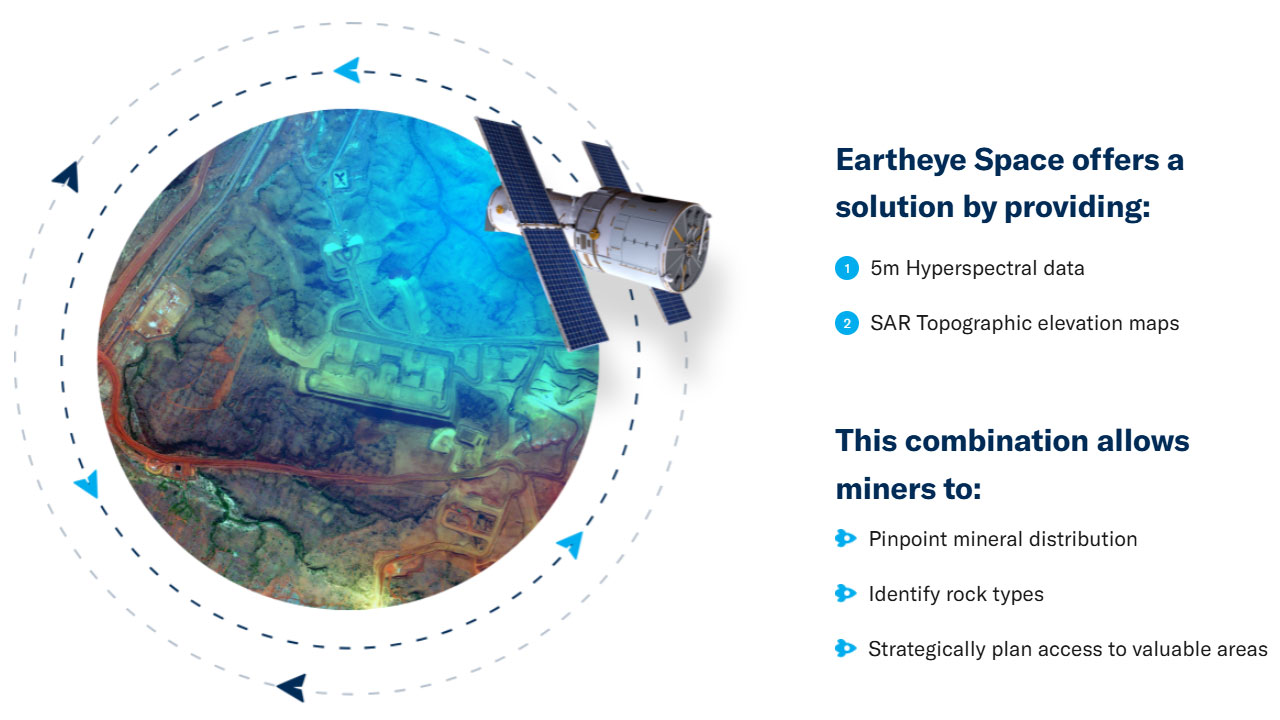

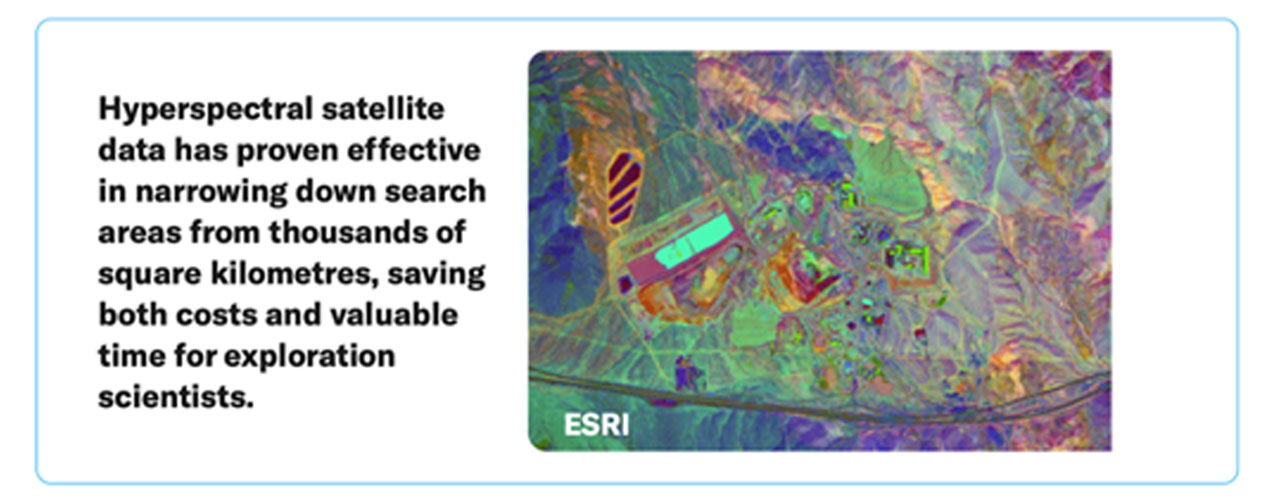

Eartheye Space’s 5-meter hyperspectral imaging and SAR-based elevation mapping enable mining companies to achieve critical exploration objectives with remarkable accuracy. The platform’s hyperspectral capabilities deliver 10× more pixels than conventional systems, supporting up to 250 spectral bands with plans to exceed 400 bands. This enhanced spectral resolution enables precise detection of subtle mineral signatures that would otherwise remain undetected.

Industry-wide adoption of satellite-driven exploration is delivering measurable benefits. Spectral analysis, synthetic aperture radar (SAR), and artificial intelligence integration enable targeted mineralisation mapping, significantly reducing unnecessary field operations while minimising environmental impact. Companies report exploration cost reductions of 30-50% compared to traditional drilling-intensive approaches, while simultaneously improving prospect identification accuracy.

Enhancing Operational Safety Through Tailings and Subsidence Monitoring

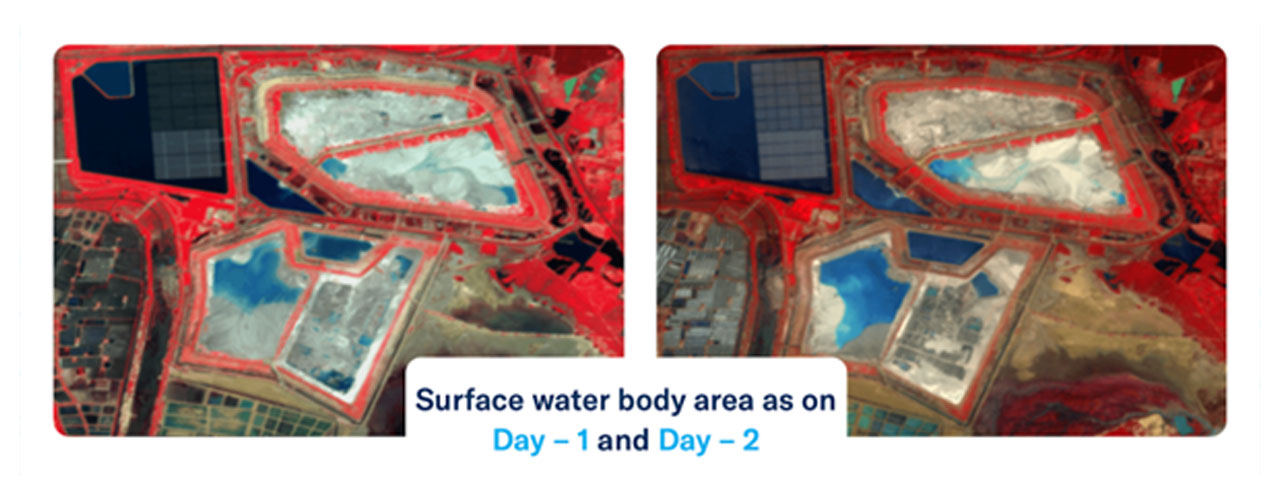

Earth observation technology offers a superior alternative to traditional ground-based monitoring systems, providing comprehensive, maintenance-free surveillance capabilities. Advanced EO platforms can track dam wall integrity, detect structural movement or subsidence patterns, and assess vegetation health as an early indicator of potential seepage or contamination issues.

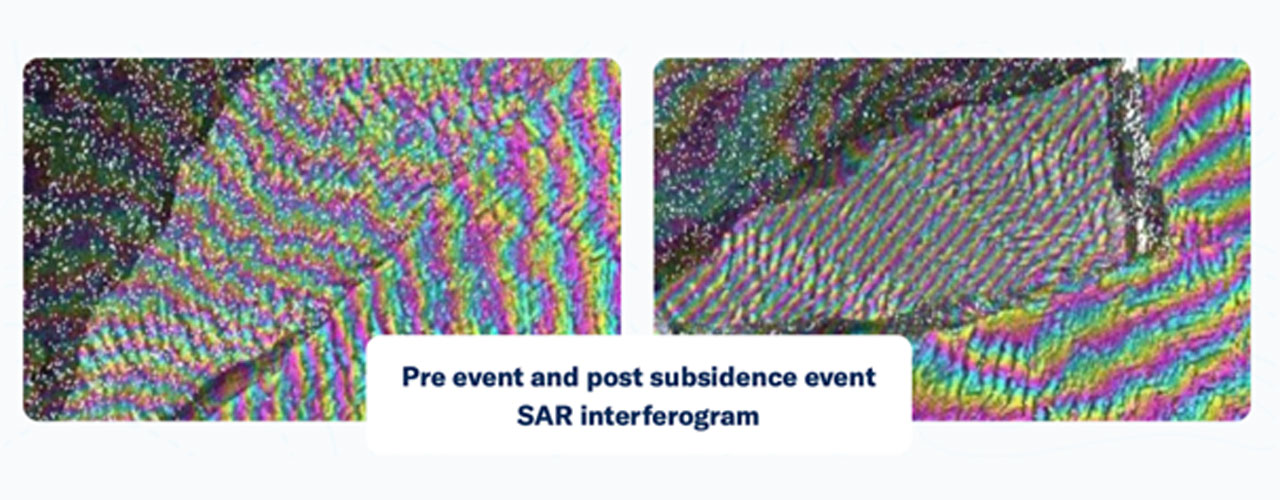

Interferometric SAR (InSAR) technology represents a particular breakthrough in subsidence monitoring. This technique can detect ground movement at millimeter-scale precision, delivering automated updates through streamlined workflow systems that require minimal setup and ongoing maintenance.

The operational benefits extend beyond risk mitigation. Remote, frequent, and reliable monitoring of tailings storage facilities enhances safety protocols while reducing operational overhead. Historical EO data enables comprehensive trend analysis and supports predictive risk modeling, while global datasets like FINEPRINT help identify areas of environmental concern across multiple jurisdictions.

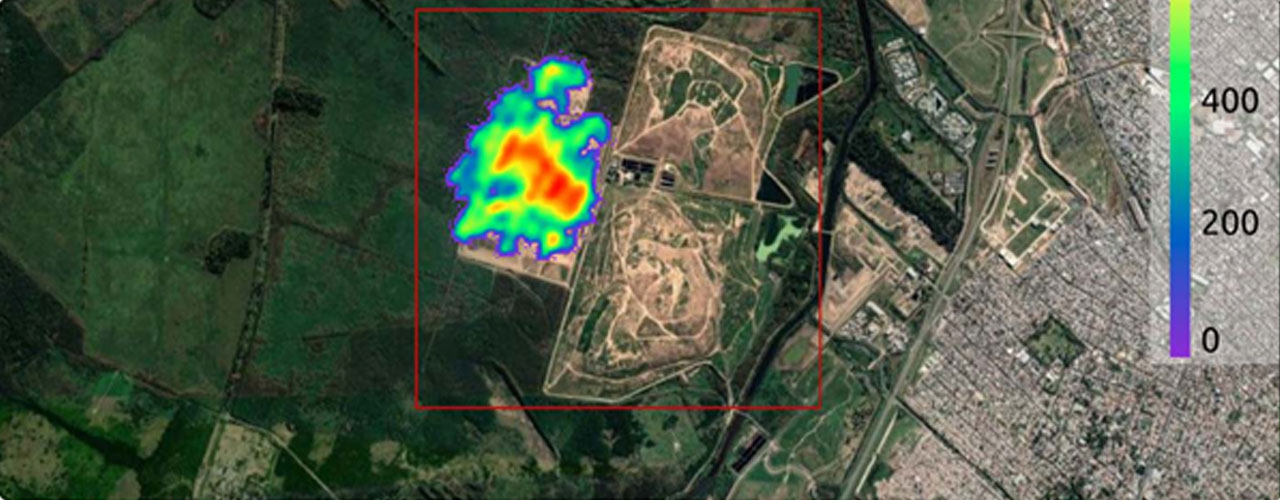

Addressing Methane Emissions Through Comprehensive Monitoring

- Comprehensive Coverage: Daily, wide-area monitoring without requiring extensive ground infrastructure deployment

- Multi-sensor Integration: Combines data from various satellite operators and sensors, providing more frequent assessments than a single satellite’s 3-5 day revisit interval.

- Real-time Detection: Near-instantaneous hotspot identification with automated heat mapping and trend visualisation

- Advanced Modeling: Sophisticated plume modeling that incorporates wind patterns, surface roughness, and temporal variations

This approach provides mining companies with the transparent, remote emission tracking capabilities essential for regulatory compliance and stakeholder reporting, particularly in geographically challenging or politically sensitive regions.

Supporting Mine Closure and Land Management

Earth observation platforms also support comprehensive mine closure initiatives by monitoring land restoration progress, vegetation recovery patterns, infrastructure removal compliance, and broader environmental outcomes. This data-driven approach enables mining companies to demonstrate regulatory compliance while optimising closure strategies.

Key Takeaway

The convergence of advanced sensors, artificial intelligence, and automated data processing is establishing new benchmarks for exploration effectiveness, operational safety, and environmental stewardship. The future of mining is increasingly defined by multi-sensor integration, automated monitoring, and comprehensive data analysis. This transformation is not approaching, it is already underway, reshaping industry standards and competitive dynamics across global mining markets.